Impact-9’s Offshore Aquaculture Solution Takes a Step Closer to Commercial Reality

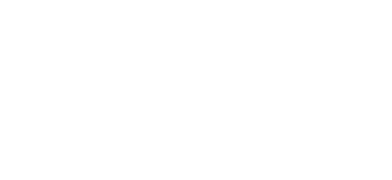

Installation Sequence of Impact-9’s Fish Containment System

Installation Sequence of Impact-9’s Fish Containment System

Start-up company Impact-9 has just completed the latest in a series of scaled laboratory tests at the Lir National Ocean Test Facility in Cork, Ireland. The project is a collaboration with MaREI, the SFI Research Centre for Energy, Climate and Marine, hosted by University College Cork (UCC), who investigated the renewable power generating solutions to be integrated with the platform.

Michael O’ Shea, MaREI Research Fellow in UCC said

” The Net9 concept has the potential to revolutionise fin fish aquaculture while at the same time opening up opportunities for decarbonising the industry through offshore renewable energy integration. At MaREI, we have begun this process of integration through the SEAI funded OARPS project in partnership with Impact 9″

Development work on Net9, including some results from testing at Lir National Ocean Test Facility in MaREI, Ireland during March 2021

A start-up company is developing technology to make aquaculture possible in open ocean environments. Currently, fish and shellfish farms must be located in sheltered bays and inlets, where there are environmental limits to the amount of seafood that can be sustainably produced. Irish company Impact-9 has designed a fish farm which can survive storms, based on an innovative flexible design that also opens possibilities for shellfish and seaweed production to be located further offshore. The technology targets a 5 billion euro growth market opportunity for sustainable aquaculture in waters around the UK and Ireland, with further opportunities globally.

Impact-9’s CEO John Fitzgerald developed his offshore engineering experience designing mooring systems for offshore wave energy systems. He told the Aquaculture Europe conference, “The unique thing about our design is how we apply flexible structural materials”. He said, “The fish we want to farm live in the offshore aquatic environment and in their natural habitat they move within that body of water. This is very different to conventional offshore designs, where engineers create human-centric, stable platforms. Providing structures that cater to both humans and fish is a real challenge, especially in extreme conditions”.

Impact-9 just completed a feasibility study funded by the UK Seafood Innovation Fund (see Note 1). This fund supports bold and ambitious tech-driven projects that enable a step-change in both the productivity and sustainability of the UK seafood sector. The UK’s Centre for Environment, Fisheries and Aquaculture Science (Cefas) administers the fund for the Department for Environment, Food and Rural Affairs (Defra). The UK Seafood Innovation Fund supports projects with a long-term vision to improve the UK seafood, fishing and aquaculture industries.

Fitzgerald said of the study, “It made everything feel real. We are now looking for a pathway to maximise the benefit to UK salmon production”. The study considers how Impact-9’s technology might leverage existing salmon production infrastructure and other blue economy developments in the UK, such as offshore wind.

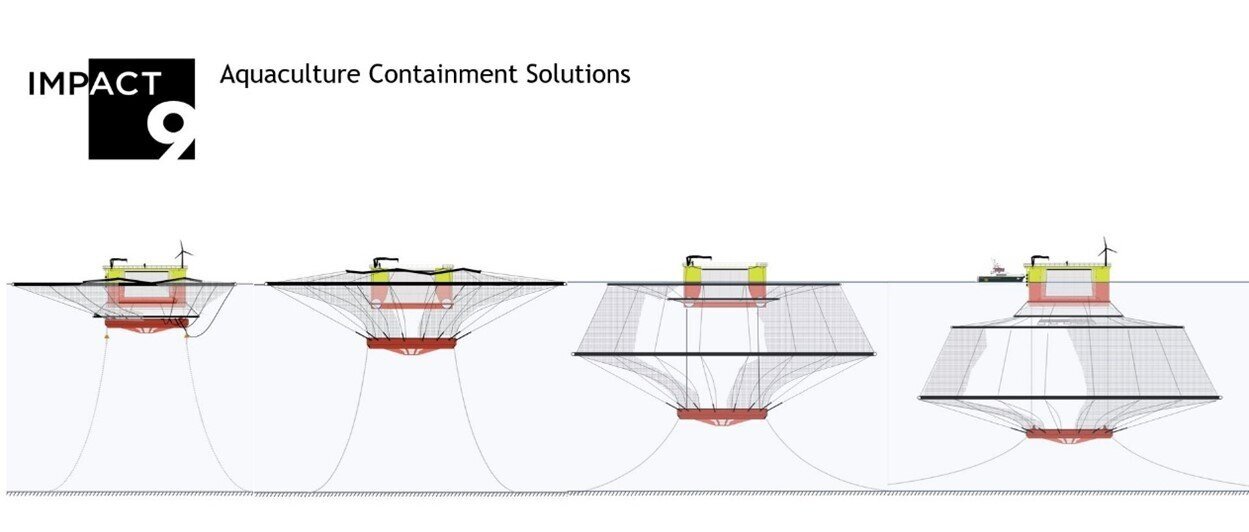

1:30 Scale Testing at Lir National Ocean Test Facility, Underwater Camera

1:30 Scale Testing at Lir National Ocean Test Facility, Underwater Camera

In his presentation, Fitzgerald offers up a tantalising low-impact fish production model, where larger post-smolt salmon can be stocked in open ocean conditions, in a submerged containment, more closely approximating their natural habitat. He told the conference, “My thinking is that at a certain stage in their life-cycle, it will be far more effective to move larger, more robust farmed salmon to an offshore zone in a submerged open containment below parasite layers and in a turbulent, oxygen-rich environment with ample capacity to disperse and break down organic emissions”. Referring to parallel technology developments in semi-closed and closed containment alternatives (see Note 3), Fitzgerald said that, “These developments are fantastic, especially for younger fish, but it becomes far riskier and more energy intensive to manage as the fish grow larger.” Noting the opportunity to gradually convert Scottish inshore production to semi-closed containment, Impact-9 envisages a combined approach using these facilities to provide post-smolt for open ocean farming. This offers a pathway to significantly increase production capacity, while greatly decreasing the environmental and wild-stock impacts from the levels seen in current production.

Working with Dublin Offshore Consultants (DOC) and UK-based fibre rope and flexible marine structures specialists Tension Technology International (TTI), Impact-9 refined their concept specification for a fish pen of 90m diameter and 125,000m3 in volume, able to produce 3000 tonnes of salmon per year in 12 month grow-out cycles. The design considers the environmental conditions of operating in offshore Scottish zones over 60m deep. The study incorporated feedback from experts at the Scottish Association for Marine Science (SAMS), the European Marine Energy Centre (EMEC) and independent farming advisor Karl Scott of Maritime Aqua Limited, in order to shape the concept and identify risks to be mitigated on the route to commercialisation.

Impact-9 has also just completed the latest in a series of scaled laboratory tests (See Note 4) at the Lir National Ocean Test Facility in Cork, Ireland. The laboratory tests and related research have been supported with financial contribution from the Sustainable Energy Authority of Ireland (SEAI) under the SEAI Research, Development & Demonstration Funding Programme 2019 (See Note 2). The project is a collaboration with MaREI, the SFI Research Centre for Energy, Climate and Marine, hosted by University College Cork (UCC), who investigated the renewable power generating solutions to be integrated with the platform. Fitzgerald says, “Our aim is to show that the system can operate in fully open ocean conditions and keep operators and fish safe, but also to show that the UK and Ireland enjoy expansive offshore zones of more intermediate exposure”. Kerrie Sheehan, Head of Department – Research & Technology at SEAI added, “SEAI is delighted to support this project led by Impact-9 in collaboration with University College Cork. It addresses the integration of renewable energy solutions for offshore aquaculture. The project provides innovative solutions for two key offshore sectors to work together.”

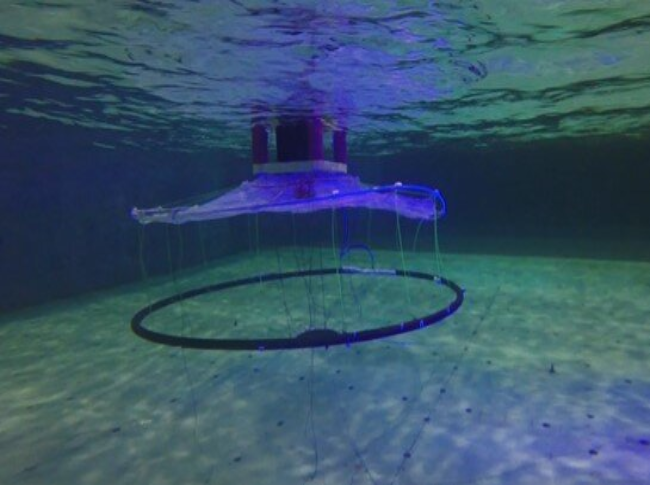

1:30 Scale Testing at Lir National Ocean Test Facility

1:30 Scale Testing at Lir National Ocean Test Facility

Noting that the current €15 billion salmon industry is highly concentrated in Norway and Chile, where there are sheltered, deep fjords, Fitzgerald says, “the semi-protected sea areas around the UK and Ireland could support an industry with a higher economic output than all of the region’s offshore wind ever could, while using only a small fraction of the marine space”. The developments also highlight the potential to co-locate offshore infrastructure for wind and aquaculture to make better use of marine space.

While the potential scale of the opportunity is not in doubt, there is more work to be done to see if the offshore approach can compete with rivals in terms of risk and cost. However, Fitzgerald observes “When we look at the economics (see Note 5) of offshore aquaculture, we find that the overall profitability can be far higher than conventional farming models. Ultimately, however, we have to prove the biological performance to convince stakeholders. That means testing”. Impact-9’s aim is to deliver the most profitable and the most sustainable approach to fish production. They believe that these objectives no longer compete with one another because of regulatory interventions and consumer demands for better welfare, sustainability, and quality. “We know this is ambitious, but everything seems to be pushing in one direction and there is a certain inevitability about it all”, says Fitzgerald.

It will take time to see which technology or combination of technologies ultimately prevail in the race for the lucrative finfish production prize. Meanwhile, Fitzgerald sees some interesting stepping-stone opportunities to help along the way. “Shellfish and Seaweed production provides a really interesting application for the very same flexible structures technology we need to validate for fin fish production concepts, but at a smaller scale”. Ireland’s seafood development agency BIM recently purchased sample mussel flotation from Impact-9 and the company believes that success in this area can put the company on a commercial footing much faster, while underpinning its finfish developments. The company continues to seek further collaborations and opportunities to bring the technology forward with a view towards delivering sea trials of their technology over the next 24 months.

Notes Referenced in Text

Note 1: For further information on Seafood Innovation Fund

Note 2: For further information on the SEAI funded project, see: Grant number 19/RDD/540

Note 3: “Semi-closed” or “closed“ refers to containment systems that are either partially or fully separated from the natural seawater. Water may be taken from the natural environment at a controlled depth, used to grow fish and then treated before being returned. This means that the stock is separated from sea-lice, while waste streams can be captured and treated. Because of the costs involved, the technology that is traditionally only employed for hatchery to smolt phases (fish typically <100g weight). However, it is being applied to increasingly longer grow-out phases and Impact-9 currently envisages stocking fish at 500g weight.

Note 4: Testing used a 1:30 scale model of the design developed for UK market conditions. The team modelled conditions representing extreme waves of up to 24 m high, collecting important data to validate how both the submerged containment as well as the overhead surface platform respond to such extreme events.

Note 5: The economic model includes considerations for the cost of 500g post-smolt for stocking, generous capital cost allowances for farm structures as well as considering a cost to license offshore production sites from the government.